Exploring the Value of Welding Evaluation in Industrial Applications: Guarding Against Failings and Enhancing Longevity

Welding examination works as a critical line of protection in commercial applications, guaranteeing the architectural integrity and integrity of welded elements. By methodically identifying problems such as porosity and insufficient fusion, assessments not just avoid failings but likewise expand the lifespan of necessary assets. Adhering to sector standards enhances both security and functional efficiency; however, the ramifications of disregarding these practices can be serious. As we analyze the diverse advantages of normal examinations, it becomes evident that comprehending these characteristics is not simply an issue of compliance but a tactical important for longevity and threat mitigation.

Duty of Welding Evaluation

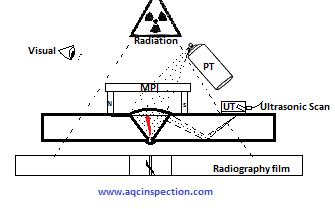

Welding assessment functions as an important secure in industrial applications, ensuring that welded frameworks fulfill specified requirements of high quality and safety and security. This procedure entails an organized exam of welds to confirm their honesty, stamina, and conformity with established codes and specs. The function of welding inspection is multifaceted, encompassing both aesthetic evaluations and non-destructive testing approaches, which might include ultrasonic, radiographic, or magnetic fragment testing.

Effective welding examination recognizes possible concerns early, mitigating the risk of catastrophic failures that can occur from inadequate welds. By making certain that welds are implemented according to develop specifications, examiners add to the total structural integrity and longevity of parts in vital applications, such as stress vessels, pipelines, and architectural frameworks.

Common Welding Problems

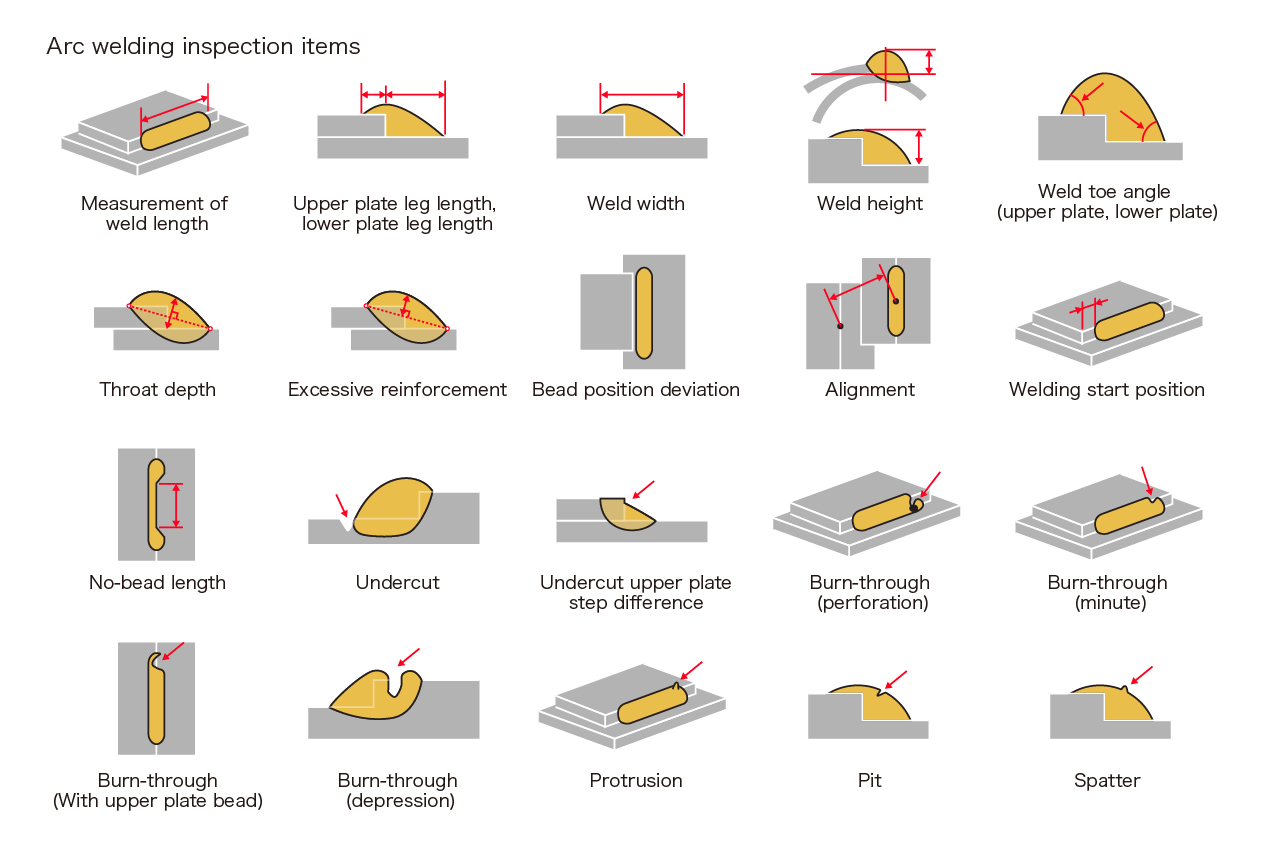

Among one of the most widespread defects is porosity, identified by tiny gas pockets trapped within the weld steel. This takes place because of pollutants or inappropriate protecting gas, jeopardizing the weld's toughness. One more significant flaw is insufficient blend, where the weld metal stops working to bond appropriately with the base material, potentially bring about structural weak points.

Splits can also establish during or after the welding procedure, often credited to thermal stresses or inappropriate air conditioning rates. In addition, undercutting, where the base steel is worn down along the weld bead, can compromise the joint and is frequently brought on by extreme heat input or wrong technique.

In addition, lack of penetration occurs when the weld steel does not reach the origin of the joint, resulting in inadequate strength. Recognizing these usual problems is essential for examiners and welders alike to ensure that welded structures satisfy safety and performance requirements, inevitably protecting against potential failings in industrial applications.

Advantages of Regular Evaluations

Routine evaluations function as a vital safeguard in guaranteeing the reliability and longevity of bonded frameworks. These assessments recognize potential defects and weaknesses that may compromise the stability of welds, enabling for prompt remediation before concerns rise. By executing an organized inspection regimen, companies can considerably minimize the threat of disastrous failings that might lead to pricey downtime, find this devices substitute, or perhaps crashes.

In addition, normal examinations add to enhanced top quality control throughout the welding process. By sticking to a regular inspection schedule, business can guarantee that their welding methods fulfill well-known high quality benchmarks and finest methods. This not only cultivates a culture of accountability however likewise motivates continual renovation amongst welding workers.

In addition, routine inspections facilitate far better maintenance preparation. By identifying damage early, companies can tactically arrange fixings and substitutes, lessening disruption to operations. This aggressive strategy eventually causes extensive possession life expectancy and improved total performance.

Lastly, a dedication to routine evaluations can boost a firm's credibility in the market. Customers and stakeholders increasingly value organizations that prioritize safety and security and high quality, consequently boosting depend on and potentially bring about increased organization possibilities.

Sector Standards and Rules

Complying with sector requirements and regulations is an essential aspect of welding inspection that enhances the advantages of routine evaluations. These requirements, established by companies such as the American Welding Culture (AWS) and the American Culture of Mechanical next page Engineers (ASME), offer a framework for finest techniques in welding processes, materials, and inspection techniques. Conformity with these guidelines guarantees that welds meet the called for top quality and safety standards, dramatically lowering the risk of structural failures.

Governing bodies like the Occupational Safety and Health And Wellness Administration (OSHA) additionally impose standards that shield workers and the atmosphere throughout welding procedures. By complying with these developed requirements, sectors can boost the reliability of their components and frameworks, guaranteeing they carry out as meant under different functional conditions.

Furthermore, adherence to industry requirements cultivates uniformity in high quality control, promoting smoother interaction among stakeholders and regulative agencies. This alignment not only decreases obligation dangers yet likewise boosts the reputation of companies in open markets. Welding Inspection Gilbert Arizona. Ultimately, compliance with welding standards and policies is not merely a legal obligation; it is an essential investment in safety, performance, and long-term operational success

Future Trends in Welding Evaluation

As industries proceed to progress, the future of welding inspection is poised to integrate innovative modern technologies that boost accuracy and effectiveness. One of the most significant fads is the fostering of automation and robotics in examination procedures. Automated systems can conduct evaluations quickly, reducing human error and enhancing throughput in producing environments.

Additionally, the integration of expert system (AI) and artificial intelligence formulas will certainly allow anticipating analytics, enabling real-time analyses and positive upkeep. By examining data from previous evaluations, these modern technologies can recognize patterns that could show possible failings, therefore extending the lifespan of bonded elements.

Furthermore, non-destructive screening (NDT) methods are anticipated to come click for more to be more sophisticated, using devices such as drones and self-governing lorries furnished with advanced sensors. Welding Inspection Gilbert Arizona. These developments will certainly enhance the capability to examine dangerous or hard-to-reach areas without jeopardizing security

Additionally, the fad towards digitalization will certainly bring about boosted data management systems that assist in far better monitoring, reporting, and compliance with sector criteria. In recap, the future of welding examination is defined by technological improvements that guarantee to significantly improve integrity, safety and security, and operational efficiency in various industrial applications.

Final Thought

Finally, welding assessment offers an important function in making sure the stability and durability of welded frameworks throughout various commercial applications. By determining issues such as porosity and insufficient fusion, routine inspections play a considerable duty in threat reduction and top quality assurance. Adherence to sector criteria and guidelines further enhances functional security and integrity. As improvements in technology remain to evolve, the future of welding examination guarantees boosted accuracy and performance, eventually adding to the durability of essential frameworks.

Welding inspection serves as a crucial line of protection in commercial applications, ensuring the structural honesty and dependability of welded parts.Welding evaluation offers as a vital guard in commercial applications, guaranteeing that welded structures fulfill specified requirements of top quality and safety. Eventually, the role of welding evaluation is important in advertising safety, boosting performance, and safeguarding financial investments in commercial infrastructure.

These standards, developed by organizations such as the American Welding Society (AWS) and the American Culture of Mechanical Engineers (ASME), give a structure for best methods in welding procedures, materials, and assessment methods.In final thought, welding evaluation serves a vital feature in making certain the integrity and longevity of welded structures throughout various industrial applications.

Comments on “How Welding Inspection Gilbert Arizona Can Boost Your Building and Production Processes”